Reducing friction is an oil’s primary function.

Synthetic lubricants have inherently superior lubricity for maximum friction reduction.

Alex Thompson | PRODUCT MARKETING MANAGER – AUTOMOTIVE, AMSOIL Inc.

Friction is defined as a surface’s resistance to relative motion. To better understand friction and its byproducts, take a moment, start rubbing your hands briskly together. If you apply enough pressure or speed, you should start to feel some heat; you may also feel fatigue and even a little wear. Now imagine rubbing your hands thousands of times per minute, and you can start to understand how engines can generate so much friction and heat. We’ve all experienced friction in our lives, but did you know there are four different types of friction?

1. Static friction is the relationship between objects at rest and is the strongest form of friction. Think of your shoes each time you take a step. Without friction, your feet would simply slide out from under you.

2. Sliding friction is the relationship between one or more objects in motion. This is the most common type of friction in automotive applications. Think of a piston moving up and down inside a cylinder.

3. Rolling friction is the relationship of an object rolling over a surface. A great example of rolling friction is your tires on the ground. Without continued propulsion, the tires will eventually come to a stop due to the friction between the rubber and the ground.

4. Fluid friction is the relationship between an object and a liquid or gas. Ever tried running in a pool? The water slows you down and it takes much more energy than running the same distance on land.

So, I hope I’ve established that friction is all around us. It’s important, but can have negative effects. We can’t eliminate friction, but we can manage it, and managing friction is something in which we’re experts. Understanding how lubricants react to various types of friction leads us to developing products that reduce wear and prolong component life, while retaining efficiency and power.

Friction not only results in loss of power and efficiency due to the extra effort required to overcome it, but it further robs power and efficiency through wear. As components wear, they lose efficiency. A piston ring against a cylinder wall results in a loss in compression and power, in addition to increased blow-by and contaminates in the oil sump that shorten oil life and result in higher levels of oxidation and sludge. As a cam lobe wears, it cannot open the intake or exhaust valves as wide, resulting in loss of power and incomplete combustion. It all starts with friction.

There are many ways to manage friction with lubrication. One way is with viscosity. The proper viscosity provides the optimal fluid barrier between moving objects, reducing friction and wear. Formulating to a required

viscosity is one thing, but maintaining that viscosity throughout the duration of the service interval or in severe operating conditions is another. Oils are subjected to conditions that can impact viscosity, such as heat resulting in thermal shear where molecular chains break temporarily and “thin” the oil. In severe conditions, another phenomenon called mechanical shear occurs, which physically breaks the molecular chains and cannot be repaired. All shear has negative impacts on a lubricant’s ability to keep parts separated.

Another way to manage friction is to use friction modifiers. Friction modifiers are commonly used in engine oils to reduce fluid friction and improve efficiency. They are also critical in supporting the separation of parts

in lower-viscosity motor oils. In other applications, like transmissions and limited-slip differentials, friction modifiers are used to dial in the correct amount of friction required for smooth operation.

The last way to manage friction is to prevent contaminants from entering the system. Contaminants like fuel, water and glycol have significant impacts on friction (thickening) or sliding friction (thinning). A robust oil manages these contaminants better than others to maintain proper viscosity. Properly formulated, high-quality synthetic oils are inherently better at managing friction than lower-quality oils because they are chemically

engineered for strength and consistency to ensure a stable viscosity in nearly all operating conditions, resisting the forces of thermal and mechanical shear. Higher detergency also makes them more resistant to

chemical contamination, while uniform molecular chains with friction modifiers lessen the impact of fluid friction making synthetic oils the best defense you can buy in the fight against friction.

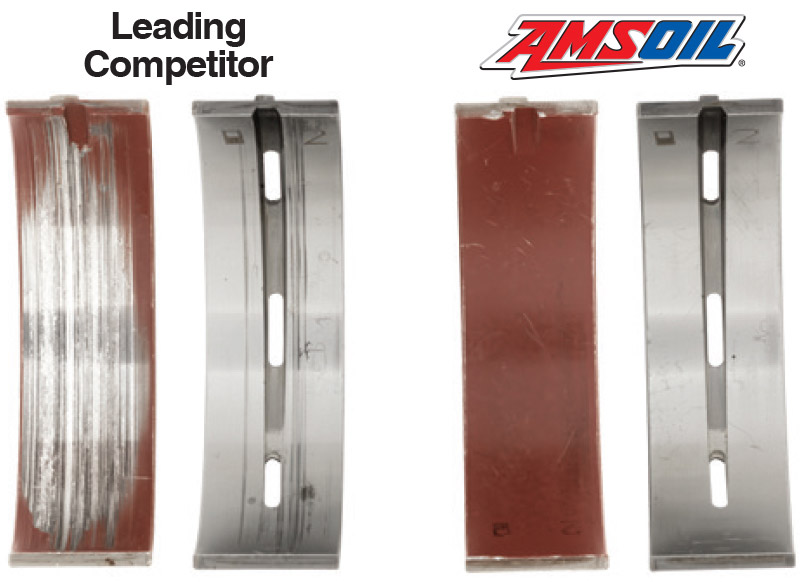

AMSOIL delivers powerful protection. How good is it? An independent lab compared AMSOIL synthetic motor oil head-to-head against a leading competitor in a 100,000-mile test.P AMSOIL provided far superior wear protection and kept bearings looking like new.

Learn more about AMSOIL and why it’s better than all other conventional and synthetic oils by visiting “Why AMSOIL Synthetic versus Conventional”

What is lubricity?

AMSOIL Dealers have access to training and study guides to help us learn more about lubrication and filtration. One of our guides is called “Engine Lubrication An Introduction to Engine Lubrication | Presented by AMSOIL INC.”

In our training we learned about various aspects of modern engine oils and why base oil and additives packages are so important. When designing a proper engine oil it is important to take into consideration all aspects of how that engine will operate. This is true for gasoline vs diesel, automotive vs powersports, tractors vs racing engines and so on.

Lubricity is the measure of the reduction in friction and/or wear by a lubricant. The study of lubrication and wear mechanisms is called tribology. Lubricity is often done by determining how much wear is caused to a surface by a given wear-inducing object in a given amount of time. AMSOIL Synthetic Lubricants go through extensive testing and wear monitoring for each formulation that is designed.

In the past we were taught that a conventionally refined miner oil has a film strength of about 500 psi before you would have metal to metal contact. We as a synthetic base oil could handle over 3000 psi before metal to metal contact. The superior nature of synthetic oil makes them the perfect solution for extending engine like by reducing friction and wear.